Ghana’s largely privatised public transport system popularly known as “trotro” may be silently endangering the health of millions of passengers, as vehicle seat architecture and fundamental engineering safety standards come under scrutiny.

An investigation by The Chronicle, drawing on engineering insights from lecturers at Kumasi Technical University (KsTU) and medical expertise from Kwame Nkrumah University of Science and Technology (KNUST), reveals that many of these vehicles are retrofitted with poorly engineered, non-ergonomic seats that violate structural safety standards.

These profit-driven modifications are often made without regard for mechanical safety, ergonomic science, or durability standards. Field measurements and observational analysis by The Chronicle indicate widespread violations, pointing to the absence of ergonomic simulation, design validation, or stress testing in trotro seat configurations.

According to global mobility reports, nearly 70% of Ghanaians depend on public transport, particularly trotros, for their daily commute. However, a widespread disregard for vehicle engineering integrity and regulatory standards by transport operators is raising red flags within the mechanical engineering and public health communities.

Regulatory Breach and Engineering Deficit

By DVLA regulations, the engineering design for public seating should include a minimum legroom of 300 millimetres and a seat interval of 700 millimetres. However, field measurements and analysis by The Chronicle suggest that these specifications are frequently violated. This indicates a lack of design validation, ergonomic simulation, and engineering testing in seat configuration.

Worse still, Ghana Standards Authority (GSA) requirements—such as proper back pans, weight distribution mechanics, anthropometric compliance, and dynamic stability during deceleration—are consistently ignored in local modifications.

ISO Standards and Public Transport Seating in Ghana

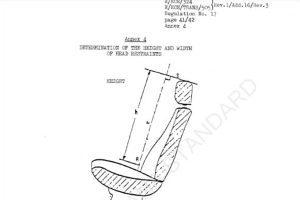

Unlike Ghana’s locally modified trotros, international standards such as those set by the International Organization for Standardization (ISO) stipulate minimum requirements for seat dimensions, backrest angles, and seating heights in passenger vehicles. These standards aim to ensure both uniformity and passenger comfort across vehicle types.

The ISO emphasizes key specifications such as seat depth and width, cushion thickness, and backrest tilt range, typically between 90° and 105°. It also evaluates seat comfort and heat/moisture transmission, which are especially critical in tropical climates like Ghana’s. Accordingly, the standard encourages the use of breathable materials and temperature-sensitive cushioning to reduce passenger fatigue.

In terms of engineering durability, the ISO defines test methods for seat load resistance and structural integrity under dynamic conditions such as braking or collisions. Passenger vehicle seats, according to ISO guidelines, must withstand impact forces to ensure safety during emergencies.

“The seats in most trotros are not designed to suit how the human body functions,” said Mr. Ebenezer Asiedu, assistant lecturer in Automotive and Agricultural Mechanisation Engineering at KsTU.

According to him, Improperly engineered seating puts pressure on the spine, muscles, bones, tendons, ligaments, joints, and cartilage. Over time, this mechanical strain can manifest as chronic pain or degenerative spinal conditions.”

Designed for Profit, Not Engineered for Safety

Mr. Asiedu explained that while imported buses are originally manufactured under ISO-certified conditions and subjected to crash simulations and ergonomic modelling, their seating systems are often modified by local operators who strip them of engineered components.

“They reduce the density and resilience of seat cushions, compress the legroom below biomechanical thresholds, and reconfigure seating rows without accounting for crash energy management,” he noted.

The absence of energy-absorbing materials or stabilisation features increases the likelihood of injury during braking or collisions. Many passengers experience oedema (swelling), nerve compression, or spinal misalignment on longer trips—signs of unsafe biomechanical loading.

According to him, headrests, which are essential for preventing whiplash injuries are mostly absent except in front-row seats, highlighting systemic neglect of safety principles.

Engineering Failures in Fabrication and Regulation

Although DVLA and GSA have stipulated engineering and material specifications, implementation remains weak. Mr. Asiedu noted that most seat constructions in informal automotive hubs like Suame follow inherited artisanal practices, rather than scientific fabrication protocols.

“There’s no mechanical testing, no load-bearing assessment, no stress-strain analysis—just welding and guesswork,” he said.

Properly engineered seating systems, he added, use vibration-dampening foam designed through dynamic modelling to absorb road oscillations. Without these, passengers are exposed to harmful resonant frequencies that can damage spinal discs and soft tissue.

Ergonomic research confirms that long-term exposure to poorly designed vehicle seats can lead to cumulative trauma disorders, including disc herniation, cervical stiffness, and impaired circulation.

“These problems develop progressively through repetitive mechanical stress,” Mr. Asiedu explained adding “the public may not see it now, but the long-term clinical burden is significant.”

He stressed that seat design must consider lumbar support geometry, anthropometric diversity, and optimal seat angles (typically 100–110 degrees) to distribute body weight safely and efficiently.

Engineering vs Informal Modification

Mr. Isaac Kofi Yaabo, an assistant lecturer at KsTU with expertise in powertrains and vehicle dynamics, described the situation as a public safety engineering failure that demands urgent redress. He explained that vehicles like the Mercedes Benz 207, originally designed as cargo vans, are illegally converted into passenger carriers—ignoring the original engineering intent.

“These modifications do not conform to stress distribution principles or safety geometry. Seats are often fixed directly without proper tests. The exposed metals used become dangerous shrapnel in the event of a crash,” he said.

Unsafe Fabrication and Material Neglect

Mr Yaabo pointed out that foreign-converted vehicles undergo proper surface treatment, impact cushioning, and design validation. Ghana’s versions, however, are often unpadded, poorly welded, and rust-prone.

He mentioned that seat height and slope are critical for joint alignment and biomechanics, but they are almost never considered.

Many seats are installed too low, causing knee compression and impaired venous return—factors that increase the risk of blood clots. He urged the DVLA, Police, and Road Safety Authority to enforce engineering-based inspections: “This is not just a transport problem; it’s an engineering failure endangering lives.”

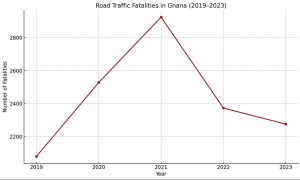

Road Accident Statistics (2019–2023)

With commercial minibuses among the deadliest vehicles on Ghana’s roads, the absence of scientifically engineered seating is not just uncomfortable it’s deadly.

According to Ghana Police MTTD data, in 2023, 8,084 commercial vehicles were involved in road accidents. Motorcycles/Tricycles witnessed 5,147 accidents.

Over 10,000 lives were lost between 2019 and 2023, with commercial vehicles including trotros—accounting for a significant proportion of the fatalities. The Greater Accra and Ashanti Regions consistently recorded the highest numbers.

Passenger Testimonies

George Asare, a commuter, said:

“Even the front seats aren’t comfortable. You can’t stretch your legs.”

Kwabena Botchwey added: “Almost all trotros exceed the legal seat count. Mercedes Sprinter, Toyota, Nissan Caravan—they’re all uncomfortable. Why aren’t the police acting?”

Clinical Effects

In an interview with The Chronicle, Mr. Prince De-Gaulle Deku, a Clinical Exercise Rehabilitation Specialist at the Department of Physiotherapy and Sports Science, KNUST, detailed the health risks associated with poorly designed trotro seating.

“Most of the injuries I have seen in trotro passengers are cuts and abrasions. These occur during boarding due to outdated vehicle structures and rusted metal surfaces,” he said. He also highlighted how improvised seat additions create cramped conditions, particularly problematic for tall individuals whose knees press against the seats in front.

According to Mr. Deku, inadequate seat height prevents passengers from resting their backs properly, resulting in spinal or lower back pain. Overused, flattened cushions further exacerbate muscular discomfort. “You are essentially sitting on a hard surface, which leads to fatigue and pain, especially during long commutes.”

Shock Absorption and Joint Damage:

Mr. Deku emphasized the importance of functioning shock absorbers. “When these wear out, every pothole becomes a health hazard,” he said. The impact is transmitted directly to passengers, increasing the risk of joint-related conditions.

He also warned about extreme heat inside vehicles due to degraded upholstery. “When sunlight hits the metal body, the absence of proper upholstery allows heat to penetrate directly, making passengers feel like they’re ‘burning’ inside the car even with windows open.”

“The seat design should mimic the natural curvature of the spine,” Deku said. However, trotro seats are typically straight and rigid. Prolonged use especially for commuters who spend over 30 minutes daily in such seats can lead to spinal dysfunction. He explained that the cumulative effect of daily exposure, coupled with sedentary lifestyles, increases susceptibility to some disorders.

Mr. Deku identified the elderly, pregnant women, and children as the most vulnerable groups. “Even though the youth may appear resilient, long-term exposure poses latent health risks,” he said.

Call for Preventive Measures:

While he refrained from urging passengers to boycott public transport, he strongly advocated for regular physical exercise. “Exercise can mitigate some of the damages from prolonged poor posture. In fact, exercise is now recognized globally as a form of medicine even for conditions like cancer.”

When asked if he had treated patients with pain attributable to public transport use, Mr. Deku confirmed: “Yes, I’ve treated people with back pain, and many of them trace their discomfort to trotro use. Some even experienced issues with their own car seats.”

DVLA Responds

Mr. Jerry Afablo, Ashanti Regional DVLA Director, acknowledged the regulatory lapses:

“We go out with the police, but we can’t be everywhere. Drivers remove illegal seats before inspection and reinstall them afterward.”

He confirmed that the legal minimum for legroom is 300mm, with a seat interval of 700mm—standards often ignored.

GPRTU Admits the Problem But Shrugs Off Solutions

Mr. Abass Ibrahim Moro, GPRTU Public Relations Officer, told The Chronicle:

“We know about the seat conversions. Some four-seaters become five-seaters. It depends on the fabricator.”

He admitted the union lacks adequate knowledge of the long-term health impacts and attributed the problem to economic limitations. In a statement that appeared dismissive of public concerns, he added: “Developing countries face these problems. We can’t always compare ourselves to developed nations.”

He confirmed that 90–95% of Ghanaians rely on public transport, and acknowledged that unsafe frame extensions are used to carry more passengers.

A National Engineering Wake-Up Call

Ghana’s iconic trotros may be efficient, but their unscientific modifications—unregulated and unsafe—are a silent public health time bomb. Passengers are paying the price in nerve damage, joint dysfunction, and even death. With engineering standards flouted, enforcement weak, and regulatory will unclear, urgent science-led intervention is the only path to safety.

The time for awareness has passed. The DVLA, GSA, MTTD, GPRTU, and Ghana’s engineering institutions must act decisively. Until then, Ghana risks becoming a cautionary tale of normalised engineering failure—paid for with the bodies of its own citizens.